From open blade razors to early safety razors

Early razors consisted of a blade that was folded into its handle for safety and opened up for shaving. This page illustrates it and explains how men used to shave with these razors – also known as cut-throat razors and straight razors – and how they were kept sharp. The page goes on to illustrate early safety razors and explain why they were safer.

____

Extracted from the memoirs of the webmaster's mother (1906-2002) and edited by the webmaster with further research

In the early 1900s when I was a child, my father used an old-style open razor, also called a 'cut-throat razor' or 'straight razor' for reasons that will shortly become apparent. He kept his shaving equipment in the alcove in the scullery which contained the only sink in the house.

Open razor: why the name?

The razor had a sharo steel blade which folded away inside a handle when it wasn't in use. In use it was completely unfolded and open, and it had to be held by its handle because the blade was so sharp. Handles could be made of various materials. The following photos show a leather handle and a bone one. They also show only covered edge to the blades, as the handles are only big enough to cover one edge. Some blades were double edged, in which case the handles would have needed to be wider.

Straight razor folded away inside its leather-covered handle

Straight razor partly folder out of its protective bone handle

Cut-throat razor: why the name?

The razor needed to be kept very sharp for a close shave, and a slight slip of the hand while shaving nicked the skin. If the nick was a deep one near the throat, the consequences could be very severe indeed - hence the name of 'cut throat'.

Men were quite experienced at using the razor safely but it was still quite common to see them with cuts on their faces from shaving.

'Straight razor': why the name?

While the razor was in use, out of its protective handle, the blade and the handle were in a straight line, hence the name 'straight razor'.

Necessities for shaving with an an open razor

Hot water

Shaving with an open razor needed hot water, both for comfort and to provide the soap lather which softened the man's stubble. Hot water, of course, was not on-tap. My mother had to fill the kettle from the single tap and arrange it on the kitchen fire so that it heated up. It stayed there until my father was ready to start his shaving.

The shaving mug

The hot water was poured into a specially shaped mug called a shaving mug.

Man's shaving mug

Shaving mugs were different from ordinary mugs. The main part was for the hot water, but there was what looked like an extra large lip which was actually a separate container for soap. In our house this was ordinary household soap, like Sunlight. The top of the mug was shaped like an open bowl with a so that the shaving brush could be rested in it, still in hot water but not slipping down completely into the hot water. This is shown in the above photo.

The shaving brush

A typical shaving brush is also shown in the above photo. The handle was varnished wood, there being no plastic at the time. The bristles were of badger hair which was soft enough for use on the skin, but tough enough to left the stubble. There were of course no man-made fibres.

A man's shaving brush

There were various styles and qualities of shaving mugs and shaving brushes

The process of shaving with an open razor

The first task was for the man to work up a lather on the shaving brush by wetting the brush in the hot water in the shaving mug and rubbing it over the soap. Then he used to brush to put lather all over the previous day's stubble.

Next he had to pull the skin taut and slide the open razor against the direction of the hair growth, so cutting off the hair at skin level. Keeping the skin taut was essential to prevent cuts and to ensure that the razor cut at skin level.

As hair and lather accumulated on the blade, my father would shake it off in the water into the shaving mug.

Shaving with an open razor.

When the entire beard that been shaved, my father splashed his face with the remaining hot water from the kettle and towelled it dry. Finally he rinsed and dried the razor and folded it securely into its handle.

How the razor was sharpened

The blade was sharpened on a special leather strap called a 'strop'. This had a fine powder applied to it to act as an abrasive.

Open razor being sharpened on a leather strap known as a strop

Early safety razors

Safety razors had an arrangement by which a specially shaped blade was held rigidly between two rectangular pieces of metal, such that the blade was sufficiently exposed to cut hair close to the skin while not cutting into the skin. Safety razors were used in the same way as the earlier razors, with shaving brushes and shaving mugs, and they, too, involved lathering the beard with soap.

Early safety razor in its case with two spare razor blades made and wrapped by Gillette

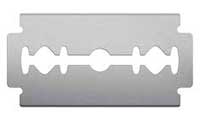

Razor blade for a safety razor. These blades were double edged so that they could be refitted the other way round when an edge got blunted in use. Note the open area in the middle which fitted the blade firmly into notched inside the razor.

These razor blades are not to be confused with razor blades used in craft which have only one sharp edge and a blunt holding strip along the other edge.

contributed by Malcolm Keen

Safety razors were definitely safer than the old, open, cut-throat type, but they had their own problems when they first came onto the market. The blades were made of carbon steel as in the Thin Gillette, Blue Gillette and 7 O'Clock brands. They needed to be rinsed and dried between uses which usually meant that the razor had to be opened up, the blade extracted, rinsed, dried and replaced - rather a rigmarole! My father's and grandfather's razors even needed to be unscrewed to achieve this.

Disposal of safety razor blades

Unlike the blades of open razors, safety razor blades could not be sharpened. Yet when they were too blunt to give a good shave, they were still sharp enough to cause damage. It was usual to have a specially fitting box to keep them in.

Box for used razor blades. A Gillette razor blade is just visible inside.

When the box was full, the contents were wrapped in layers of newspaper and put into the dustbin.

Photos by the webmaster with acknowledgments to West Somerset Rural Life Museum and Fagans Museum of Welsh Life

| sources | webmaster | contact |

Text and images are copyright

If you can add anything to this page or provide a photo, please contact me.